-

Info@cleanmakeproducts.com -

+91-9724551561 - Send SMS

- Send Email

- GST No. 24AAZPD3653M1Z7

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

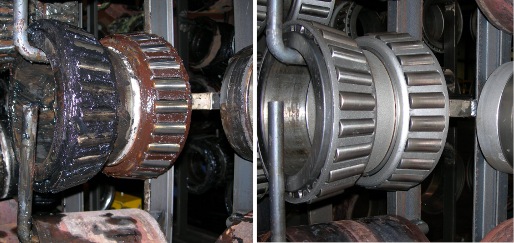

CLEAN MAKE Power Washers are in common use worldwide to clean bearings for inspection and reconditioning. The industries serviced by CLEAN MAKE Systems are: Rail shops specializing in bearing rebuilding, Aircraft Overhaul Shops, Steel and Aluminum Rolling Mills, OEM Bearing Rebuilders, and the Military. In all cases, the CLEAN MAKE Cleaning Process is fast and certain, and the cleaning standards are consistently met.

In this machine more than 10000 Bearings can wash per day CLEAN MAKE also has many Bearing Washer installations in Steel Mill Shops. Aircraft Bearing Rebuilders prefer the speed and thoroughness of the CLEANMAKE process. In all cases, the CLEAN MAKE system consistently meets the cleaning standards for bearing cleaning. All Power Washer models are available for batch or automated operation. Bearing Fixtures load outside the Cabinet for fast Table loading to maximize uptime and productivity. Various Fixture sizes are available.

CLEAN MAKE Bearing Washers can be provided in Batch, Semi or fully automated configurations. Bearing washing generates high volumes of waste grease. Each rail bearing, for example, can have one pound of grease so that, in one day’s operation, the solution reservoir could load with 500 or more pounds. CLEAN MAKE offers exceptional Sludge Management Systems including its Sludge/Surface Scraper and AirLift System, Sludge Surface Scraper, Coalescing Oil Removal System and Oil Skimmer to extend solution life for fewer cleanouts.

The inner races, and rollers or ball bearings, clean the same as the outermost surfaces. A CLEAN MAKE will prewash complete Bearing Assemblies before dismantling to come apart faster. The shop stays cleaner and more productive because all the sludge remains inside the Cabinet. As with rail bearings, large amounts of waste grease is generated so that CLEAN MAKE Solution Management Systems are especially useful to (1) extend solution life and increase uptime and productivity, while (2) reducing the cleanouts and operating expense, and (3) saving chemical and service labor.

CLEAN MAKE Power Washing is capable of Deep Cleaning so that all bearing surfaces, even the cavities and races that are not readily accessible from the nozzle blast, wash thoroughly clean. Whether the bearings are on fixtures or in baskets, there are many shaded areas in the load, yet Power Washing reaches them all. The Comparison and Pump Technology explain the advantages and benefits of the CLEAN MAKE system.

Opration :

- Feeding Job inside The machine chamber

- Clamping job

- Washing by high pressure liquid, oil

- Dry by heavy blowers

- Lubr icat ing operat ion

- In last heat by heat air blowers and packing

- All job count ing by digit al screen

- CNC, PLC Available as per requirements

Specifications

| Description | Specification |

| Overall Dimensions | 10 Feet L ´ 2 Feet W ´ 4 Feet H |

| Washing Media | MTO |

| Filtration system | Paper Band Filter, 5 / 10 micron |

| Total Electrical power required | 3 H.P. |

| Washing spray Pressure | 1.5 bar pressure |

| Component size range | Min 50 To 500 MM |

| Washing efficiency | 0.003 mg |