-

Info@cleanmakeproducts.com -

08069247354 Ext : 161 - Send SMS

- Send Email

- GST No. 24AAZPD3653M1Z7

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

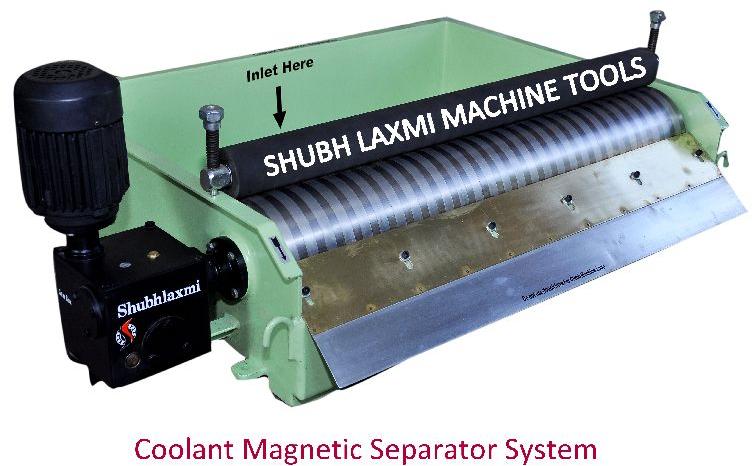

We Clean Make Products L.L.C ( Shubh laxmi machine tools ) ( amba engineering works ) is the very first and leading manufacturer in providing solutions for coolant filtration and Paper band filters With 40 years of development and manufacturing experience, we have developed an extensive product range that can meet customers' needs for filtration products. Magnetic Separator and Paper Filter are our fundamental products since 1975. Our various coolant filtration systems can remove fine contaminant from 50 micron to 1 micron of particle size, therefore significantly extend the life of coolant and improve surface brightness. Our products have extensive applications for machine tools, such as Grinding Machine, Honing Machine, Lapping Machine, CNC tool and cutter grinder, Machining Center and more. These solutions not only help achieve environmentally-driven projects at your facility, but also keep valuable metal alloys separate to maximize their value in recycling.

With over 40 years of experience in delivering solutions that provide significant savings and quality improvements for metalworking and recycling operations, we can always fulfill customers’ needs and provide benefits

How It Works :

- The contaminated liquid flows into the coolant filter by gravity or by pressure into the magnetic separator :

- The jet breaker

- Evenly dispersed the flow, as the contaminated fluid enters the separation chamber

- The rotating magnet unit

- Collects the magnetic particles, which are subsequently removed by a special comb-blade

- Passes to a containment tank.

- Which also pushes the sludge

- The cleaned liquid

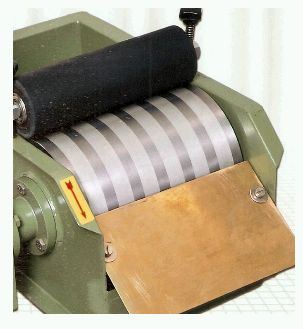

Magnetic Drum :Magnetic drums possess higher strength in comparison of electromagnetic drums. These permanent magnetic drums are made using magnets, which are long lasting in quality and useful for whole of the life. The power of these magnets Drum does not reduce during normal use. Volume of material which can be handled by magnetic drums depends upon the diameter & length of the drum Size Range the larger the diameter and width of the drum the greater is the volume of material which can be handled. Magnetic Drum Have strong strength with power Full Magnetic Capacity. It can Remove up to 1 Micron Very Easily. This Magnetic Drum Made From M.S & Aluminum Rings which have very long Life. This Magnets are useful for removing magnetic contamination with low magnetic properties and fine iron particles are to be separated. Magnetic drum separator is a self cleaning type system used for separation of Iron.

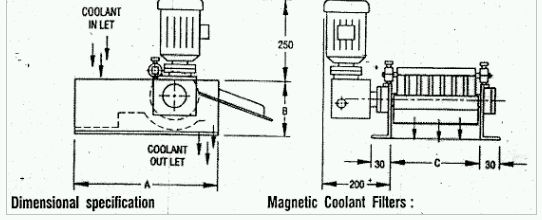

Specifications

| Capacity In L.P.M |

A |

B |

C |

Motor H.P |

Drum R.P.M |

Magnetic Drum Size |

30 |

350 |

150 |

150 |

0.25 |

2.3 |

D 150 X 130 L |

50 |

350 |

150 |

205 |

0.25 |

2.3 |

D 150 X 185 L |

65 |

400 |

150 |

280 |

0.25 |

2.3 |

D 150 X 260 L |

100 |

400 |

150 |

380 |

0.25 |

2.3 |

D 150 X 360 L |

150 |

500 |

200 |

580 |

0.50 |

2.3 |

D 150 X 560 L |

200 |

500 |

200 |

620 |

0.50 |

2.3 |

D 150 X 700 L |

300 |

550 |

200 |

720 |

0.50 |

2.3 |

D 200 X 600 L |

400 |

550 |

200 |

720 |

0.50 |

2.3 |

D 200 X 700 L |

500 |

550 |

200 |

820 |

0.50 |

2.3 |

D 200 X 800 L |

Graph